By signcraft

Posted on Wednesday, September 21st, 2016

Last week we asked Trade Secrets readers to help us out with a survey to find out how sign shop owners price their work. Many thanks to the hundreds who responded! We really appreciate your taking the time to participate.

The results give us all an inside look at how sign shop owners estimate and price their work, and why they think signs are underpriced. Here’s what we learned:

They were experienced.

Let’s start with a look at the experience level and the shops of those who participated. They were experienced shop owners. Most of them—86%—had been in the business eight years or more, and most handled non-illuminated signs (flat signs, vehicles, 3D signage, etc.):

58% owned commercial sign shops (primarily non-illuminated signage)

26% owned full service sign shops (both non-illuminated and illuminated signage)

The remaining 15% had either specialty sign shops or were a part-time/freelance sign shop.

They use several estimating approaches.

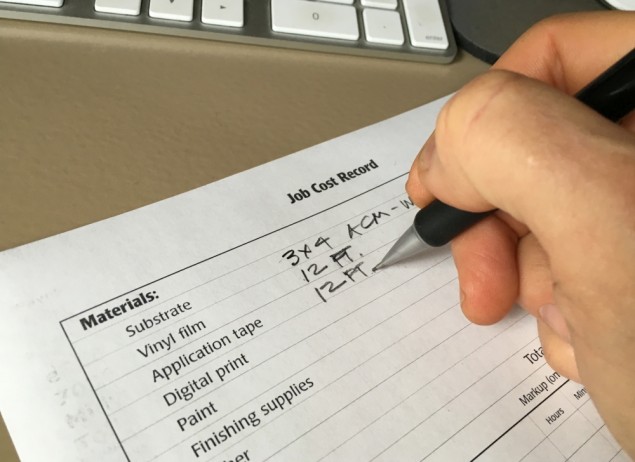

When asked what approach they use to estimate sign prices most often, manual estimating (calculating the material cost and estimating the time involved) topped the list. Relying on experience came in second:

46% said they manually estimate the time and materials on most jobs

32% said they relied primarily on experience

12% said they use estimating software for most jobs

10% said they use SignCraft’s Sign Pricing Guide, either in print or online, most of the time

Several of the respondents said they had developed spreadsheets that they used to estimate most jobs. Some said they had developed square footage rates for common projects.

But all said they used more than one of these approaches for their estimating. For example, 37% said they also used SignCraft’s Sign Pricing Guide, either in print or online, for some of their estimates.

Their approach varies with the sign’s complexity.

Next we asked which approach they would use to estimate a selling price on three routine projects. Not surprisingly, the higher the value of the sign, the more likely they were to estimate the project manually.

Why are signs underpriced?

When asked what they felt was the main reason signs were underpriced, 42% felt their competitors didn’t know how to accurately price their work, which depressed the market. 29% felt the problem was that customers were unwilling to pay what signs are worth. 10% felt there was too much competition in their market, which drove prices down. 10% had another reason, and 8% felt that signs were not underpriced.

They had more to say.

Many shared their comments on the subject of pricing, and we wish we had room to share them all here. (Thanks, too, for the suggestions on survey improvements. We’ll put them to work on the next one.) Here’s a sampling of what they had to say:

“I think through all steps, logging time in a minimum of 15-minute increments, being sure to include consult time, administrative time, each production step, etc. I figure delivery and installation as a separate thing, and include everything from loading the truck to setting up ladders, plus time for clean-up and putting things away. I also mark up materials, usually from 25% to 60%.”

“Generally, I use time and materials and then compare it to either other projects that we have done, or to SignCraft’s Sign Pricing Guide if it is applicable.”

“I think sign shop owners don’t, or are afraid to, charge what they should for the advertising value of their work.”

“Our industry would benefit if we all sold on the value of the sign, not the materials and labor. Unfortunately, in our area, we have competitors that are fighting each other for the lowest price, which hurts the entire market.”

“I would guess your Sign Pricing Guide has transformed MANY shops from ‘just getting by’ to being profitable!”

“My experience as a wholesale supplier to the sign trade years back showed me that many new entrants to our trade lack the experience to properly price the best-selling sign products. They can destroy a market by engaging in price wars without knowledge of the trade or the costs associated to support a market in the long run. Many of these newer shops aren’t creating an investment with a return, they’re just creating a ‘job’ for their owners and business with no true marketable value. The advances in production equipment and media makes our trade seem simple. That’s tempting to small investors, but they often act like old time ‘snappers’—grabbing all the high margin work by offering low prices, then closing their doors within a few years from bad pricing policies. Shops have to adapt by seeking a return on their investment that beats any other financial offering—on every project, large or small.”

“I have always thought that pricing is harder than doing the work. It seems hard to be fair to yourself and the customer at the same time. Maybe it’s because I wear too many hats. If it was my job to just price signs and not deal with the customer, it might be easier. Say you know that the job used hardly any materials but took you 45 minutes to produce. You know you really should charge your shop rate of $75 per hour but the job looks like it should cost $20. It’s easier for the guy that wears only the pricing hat to charge the right amount.”

“I appreciate that SignCraft works to help signmakers become successful, not just sell advertising in its pages.”

“I love your Sign Pricing Guide. It has sure simplified my life and saved me hours. I still often calculate my time and materials, but usually come within a few dollars of your Pricing Guide. Good work!”

“My bread and butter is vehicle graphics. The main comment from my regular customers is ‘You make it easy.’ That is what I strive for—that’s how I keep my customers. I know the temptation they face for ‘cheap’ prices from competitors, from having talked with a few franchise sign store owners who are grossly underpricing their signs ‘to make the sale,’ as they say.”

“Estimating sign and design is definitely the hardest part of my job!”

“One of the biggest problems to overcome is general lack of knowledge and skills. Our market is saturated with inexperienced designers and poor business managers. They do poor quality work on inappropriate substrates, and charge outrageously low or high prices. This gives the local industry as a whole a huge obstacle to overcome in educating customers on quality design, quality work and a premium (but fair) price.”

“For most jobs, I figure material cost and my time. I add my shop rate, and check my price against the online pricing at www.signcraft.com. It’s easy to check on my smartphone.”

“It is very difficult to understand why a heating and cooling company or a plumber or a mechanic can get $85 per hour, but a $50 per hour shop rate for signs seems excessive to many people.”

“We have to quit underpricing our work and giving away our layouts and artwork. Full-color printers have affected the industry like the vinyl cutters did back in the ’80s and ’90s for the sign painters. A one-size-fits-all square foot price will not work for all signs. I tell my customers, ‘Buyer beware’ if a price is too much cheaper than mine.”